Individual Solutions for your Company

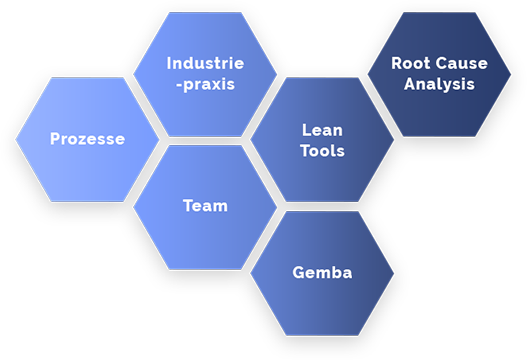

Lean Business Systems

What is Lean Business Systems

Medium-sized industrial companies face multifaceted challenges to achieve sustainable business success.

- Recognise and understand future marktet opportunities and customer requirements.

- Develop innovative and profitable products.

- Purchase cost-effective materials with short lead times, manufacture the product and deliver to the customer.

- Enable both high quality and low costs.

- Ensure sustainable earnings for the long term.

- Motivate employees.

- Ensure customer satisfaction and in turn secure the future of the business.

The many departments of a company follow different objectives to meet business goals:

It follows that

It follows that

- Sales wants to sell at the best price,

- Engineering wants to develop the most technically sophisticated product,

- Purchasing wants to buy at the lowest cost,

- Production wants to run at pace and capacity,

- Service wants to offer 24/7 availability,

- Shareholders want to earn money.

The objectives of individual departments are often contradictory. Mutual agreement cannot be found, amplifying problems and leading to collapse of the company unless specific countermeasures are implemented.

The wave model embodies Lean Business Systems. It visualises how problems arise, their impacts and how they can be avoided.

LEAN BUSINESS SYSTEMS IDENTIFIES ROOT CAUSES AND SOLVES PROBLEMS.

Leadership

More than 80% of the problems facing companies can be attributed to leadership, 15% can be traced back to lack of expertise and no more than 5% are due to lack of employee motivation. Whilst people management is challenging and cannot be directly measured, it is the KEY to business success. Leadership at Lean Business Systems means:

- Leadership should be reserved for those who wish to lead.

- Experts in their field of expertise rarely make the best leaders.

- Employee motivation is intrinsic, demotivation is extrinsic.

- For a team to be successful the leader must identify what motivates of each individual team member and foster targeted support.

- The greater the alignment between individuals’ objectives the greater the prospects of success.

- That means on the other hand: Consequently remove unmotivated and underperforming employees from the team

- Use fewer and simpler leadership tools. These include timing plans, task lists, profit and loss statements, process charts, VSM (Value Stream Maps).

- Concentrate on facts and figures.

- Communicate clearly and openly.

- Use the 5-W-Method consequently - why, why, why, why, why.

- Gather the opinion of others, however as the responsible person decide for yourself.

- Clearly assign tasks and responsibilities.

- Foster clarity and transparency.

- Always delegate departmental tasks to the departmental level.

- Put together balanced teams according to age, experience, gender and personality.

- Give employees opportunity and be on the lookout for talent in the 2nd and 3rd tiers of the organisation.

- If experts cannot be found within the company, hire them externally.

The best way to achieve mutual success is to selectively foster positive employee qualities and identify their motivation factors.

Gemba

Gemba originates from Japan and can be understood to mean „where it happens“. It is one of the main pillars of Lean philosophy. As a leader, Gemba means to form your own opinion on the ground, to complete so called reality checks. These are referred to as Gemba Walks.

- To speak to the employees who complete the first production process of the manufacturing chain, the man at the machine or the woman in the assembly area.

- Let others show you the workflow, step through the process, ask questions.

- Operational supervisors must be involved in the Gemba Walks.

- Tasks with completion dates are assigned in the work setting to the responsible persons and are recorded on Lean Boards.

- Call in experts as required. Check information for plausibility.

The challenge is to use Gemba Walks consequently and regularly. Where possible every day.

Over time it is possible to form a complete picture of the situation by repeating the process regularly. The employees develop faith in the process because they feel they are being taken seriously. This can be reinforced by the 5-W Method. Duplication of meetings can not always be avoided. The fundamental point is that results, objectives, tasks and responsibilities are visualised in the work setting. Gemba Walks are not constrained to the manufacturing area and can be effective in indirect departments such as purchasing, logistics and sales.

Gemba Walks soften the peaks of the Lean Business Harmonisation Model, which are also visible in the production area. Initially they are a tactical instrument to document daily problems and to resolve them. The bi-product is information on the real root causes of problems. With this information problems can be focused upon. With this focus, problems are solved rather than just moving them temporarily out of the way.

Over time it is possible to form a complete picture of the situation by repeating the process regularly. The employees develop faith in the process because they feel they are being taken seriously. This can be reinforced by the 5-W Method. Duplication of meetings can not always be avoided. The fundamental point is that results, objectives, tasks and responsibilities are visualised in the work setting. Gemba Walks are not constrained to the manufacturing area and can be effective in indirect departments such as purchasing, logistics and sales.

Gemba Walks soften the peaks of the Lean Business Harmonisation Model, which are also visible in the production area. Initially they are a tactical instrument to document daily problems and to resolve them. The bi-product is information on the real root causes of problems. With this information problems can be focused upon. With this focus, problems are solved rather than just moving them temporarily out of the way.

Root Cause Analysis

In the approach to problems, more often than not the obvious solution is selected. The step of analysing the problem is skipped. This leads to a trial and error search for the real solution. This approach eliminates the symptoms of the problem, however disregards the root causes and their solutions.

The elimination of symptoms yields quick results. They are however rarely sustainable and serve only to delay solving the problem. This is further exacerbated by repeatedly working through the Problem - Solution cycle. This leads to project delays with no measurable improvement over a long period of time.

The quintessence of Root Cause Analysis is to identify the causative factors behind problems. Once known, the solutions are usually obvious.

These can be identified by applying the DMAIC-Method (define – measure – analyse – improve - control), the PDCA-Method (plan – do – check - act) and the 5-W-Method.

The root cause analysis starts where the problem is first visible. Working backwards from that point to the start of the process chain, each process step is analysed until the source of the problem has been found. Whilst costly and time consuming, this is the only way to solve a problem.

The elimination of symptoms yields quick results. They are however rarely sustainable and serve only to delay solving the problem. This is further exacerbated by repeatedly working through the Problem - Solution cycle. This leads to project delays with no measurable improvement over a long period of time.

The quintessence of Root Cause Analysis is to identify the causative factors behind problems. Once known, the solutions are usually obvious.

These can be identified by applying the DMAIC-Method (define – measure – analyse – improve - control), the PDCA-Method (plan – do – check - act) and the 5-W-Method.

The root cause analysis starts where the problem is first visible. Working backwards from that point to the start of the process chain, each process step is analysed until the source of the problem has been found. Whilst costly and time consuming, this is the only way to solve a problem.

Processes

The customer comes first at Lean Business Systems.

He or she usually has two contact points with the company: at the beginning during the acquisition and at the end with delivery of the product. Between contract and delivery to the customer there is a chain of process steps.

Companies are usually organised into departments. Each has individual tasks and objectives which are to be optimised. From department to department however these tasks and objectives are contradictory.

The result of each individual department optimising according to their own objectives? Optimal ineffectiveness: the worst of all worlds. The customer disappears from view because individuals are focussed on the best possible performance in their own areas.

By focussing on the process instead of the individual functions, Lean Business Systems breaks this cycle. What counts, and what must be right, is the end result. The alignment of, and in parallel the improvement of all performance indicators across the entire process leads to an optimal result for the customer. This is the task of management and is successfully practiced and implemented by Lean Business Systems.

He or she usually has two contact points with the company: at the beginning during the acquisition and at the end with delivery of the product. Between contract and delivery to the customer there is a chain of process steps.

Companies are usually organised into departments. Each has individual tasks and objectives which are to be optimised. From department to department however these tasks and objectives are contradictory.

The result of each individual department optimising according to their own objectives? Optimal ineffectiveness: the worst of all worlds. The customer disappears from view because individuals are focussed on the best possible performance in their own areas.

By focussing on the process instead of the individual functions, Lean Business Systems breaks this cycle. What counts, and what must be right, is the end result. The alignment of, and in parallel the improvement of all performance indicators across the entire process leads to an optimal result for the customer. This is the task of management and is successfully practiced and implemented by Lean Business Systems.

Lean Tools

Lean Business Systems consistently applies existing and self developed Lean Tools which are proven in practice. These are consolidated into a tool box and applied as required to develop individual solutions.

All of the tools used have the following in common:

All of the tools used have the following in common:

- Easy to understand and quick to use.

- Results-driven with respect to time and money.

- Use key figures as a measure of effectiveness.

- Are structured to work together in sequence.

- Based upon cause-effect process principles.

- Concentrate on the essential matters to be solved.

- Enable transparency through visualisation: The use of white-boards, stand-up-meetings, action lists, graphs and trends.

Regular reviews and reporting including deviation analysis highlight the current status.

The key factors for the effective application of Lean Tools are:

- Motivated employee teams fully engaged in problem solving,

- the regular and frequent use of tools, preferably in the work area, and

- the clear, transparent visualisation of tasks, responsibilities, objectives and results.